The need for purity within microelectronics and aerospace piping systems is a common topic in our industry.

Cleanliness must be guaranteed. Cleanrooms and the welders and fabricators who work in them are essential to meeting the strict requirements in these applications.

Companies love bragging on their cleanroom capabilities. We certainly do. But let’s dig deeper. What makes a cleanroom a cleanroom? What systems must be in place to maintain the environment? How do those systems work? What does it mean for customers?

Vetting cleanroom welders is a common challenge among customers in our industry. We believe transparency can lessen that burden.

Cleanroom classification

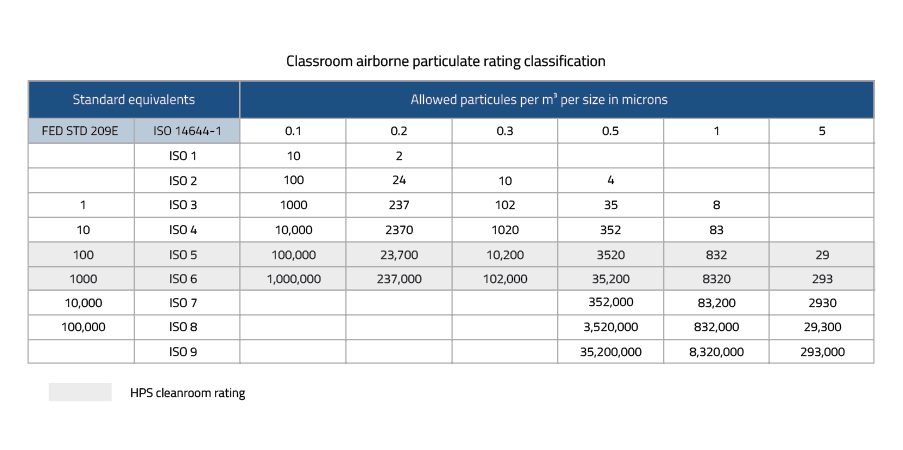

Even the smallest microscopic particles can cause serious problems if they contaminate ultra-high purity systems. Cleanrooms are rated based on how well they keep particles out of the air.

The chart below includes the International Organization for Standards (ISO) cleanroom classes. The classes are described in ISO 14644-1. In addition, the classes are shown alongside their Federal Standard 209E equivalents. (While FED STD 209E was canceled in 2001 in favor of ISO 14644, it remains the preferred way to express cleanroom airborne particulate standards in the U.S.)

As the highlighted portions of the chart indicate, our cleanroom is Class 100- and Class 1000-rated (ISO 5 and ISO 6).

Air cleanliness in our cleanroom

We built our cleanroom in 1996 inside our existing fab shop. The space is about 40 feet by 40 feet and is separated into three main areas.

First, a small gowning room was built at the entry. Further in are the actual work spaces. The Class 1000 side is first, followed by the Class 100 side. The two workspaces are separated by a static-dissipative vinyl curtain to help prevent the attraction of particles as well as surface charges.

The room is under constant positive pressure. If it’s breached, air can only move outward, never inward.

The pressure originates on the Class 100 side, flows under the curtain to the Class 1000 side and finally travels to the gowning area and outward from there. Six HEPA filters are installed in the ceiling above the Class 100 workspace. Another HEPA filter is installed in the ceiling on the Class 1000 side. All the air return grills are located on the Class 1000 side of the cleanroom.

The way the HPS cleanroom is designed provides a key benefit: While the workspaces are separated according to separate air cleanliness standards, the air in the Class 1000 side is routinely much cleaner than its rating indicates because all its air is fed from the Class 100 side.

For that matter, the filtration in the Class 100 side exceeds that standard and approaches the next-highest air cleanliness rating.

Temperature and relative humidity are also kept constant in our cleanroom—between 64 and 68 degrees Fahrenheit and between 35 and 40% relative humidity. The relative humidity is especially critical because much of what we make in the cleanroom is subject to quality standards intolerant of excessive moisture. However, the risk of static electricity in the environment increases when humidity falls below 35%. Static electricity is harmful to sensitive electronic components.

Cleanroom protocol

Anyone entering the cleanroom must gown up head-to-toe immediately. We supply booties that fit over shoes and boots while keeping a sticky mat at the entrance to the gowning area to snare any lingering particles on footwear or the floor.

Segregation of raw materials is also critical in process piping, whether for a high-purity application or not. The corrosion-resistant 316L stainless steel we use for cleanroom welding and fabrication projects is always kept separate from ferritic materials to eliminate corrosion risk.

No ferritic materials are allowed in the cleanroom at any time for the same reason.

We also have a strict policy for the welding and quality testing equipment used in the cleanroom: Once it’s in, it stays in.

When we finish a project, it heads to a packaging station within the cleanroom. There, we double-bag and seal the work. The package is filled with an inert gas to guarantee it stays as clean during shipping as it was during manufacturing.

How do you clean a cleanroom?

It’s all about ensuring no particles or moisture enter the space.

That’s why we never use water to clean equipment or surfaces. Instead, we use 70% isopropyl alcohol. And no paper towels or flannel rags, either. The risk of contamination is too high with those materials, so we only use synthetic cleanroom wipes.

Craftsmen are our greatest asset

Cleanrooms play an important role in ensuring optimal performance of ultra-high purity systems and components in aerospace and semiconductor applications.

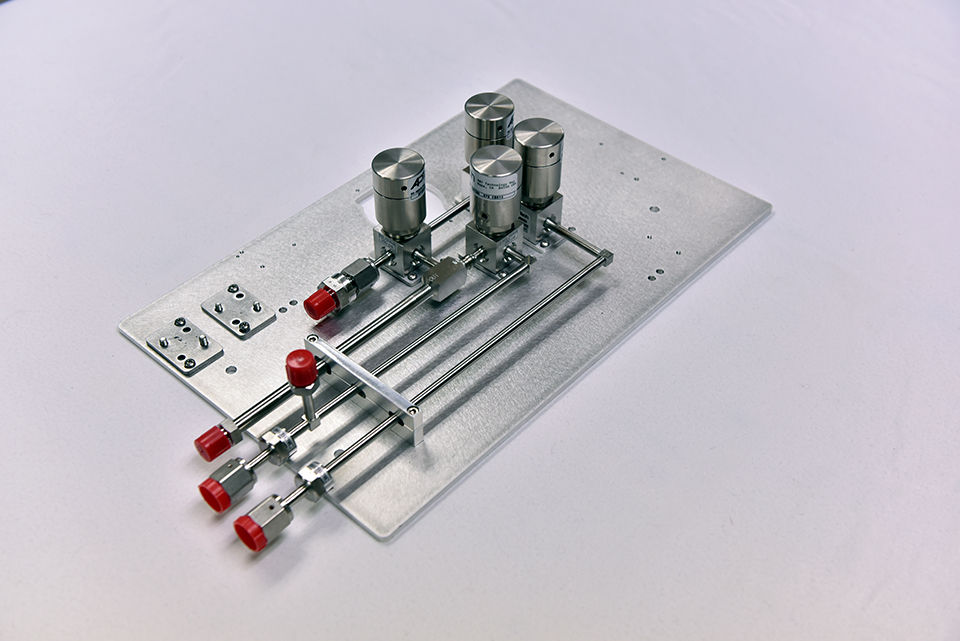

But we believe the people who work in these spaces are even more critical to customer success. Experience matters—see why here. Our craftsmen are responsible for these flagship cleanroom welding and fabrication projects:

- Prototyping and subsequent production of 18 gas purification suitcases for remote launch purging used by NASA.

- Fabrication of a replacement ultra-high purity valve panel for a semiconductor customer as an alternative to their OEM.

- Emergency replacement of a dusted silane line following an improper cycle purge inside a semiconductor manufacturer’s facility.

The skilled fabricators and welders we employ are certified to all applicable ASME & international SEMI standards. And, their work is backed by enhanced weld quality testing tools and methods we patented to guarantee we meet customers’ most extreme requirements.

If you want to discuss how the combination of the right people, the right tools and the right environment can enhance your operations, let’s connect.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.