The ways industrial piping systems and components are manufactured have evolved to meet the challenges posed by severe service environments in many industries.

In some cases, the transmission and conversion of corrosive raw materials must be carried out in high-heat, high-pressure settings. Higher-performance formulas that can stand up to significant stress and corrosive attack are required in these instances.

The chemistries of Hastelloy, Inconel and other nickel-based formulas are ideal for use in these settings.

Nickel-based superalloy properties

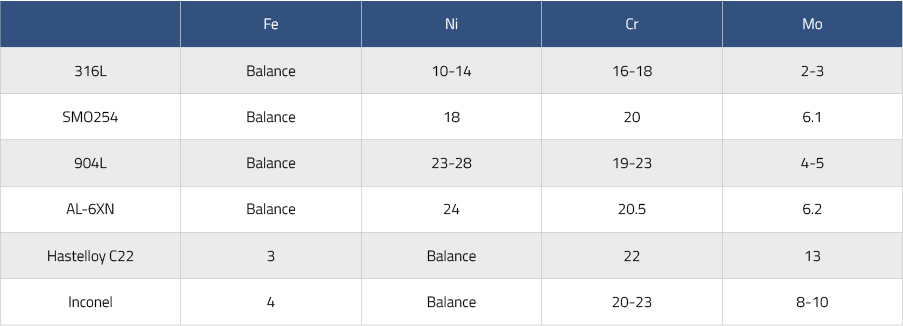

Many high-performance formulas used in industrial process piping contain nickel as one of the key alloying elements (others include chromium and molybdenum), but they are iron-based. This means that, whatever other alloys are present, the remainder—and the largest share—of the formula is iron.

Popular high-performance formulas fitting these criteria include 300-series austenitic stainless steels as well as similar super-austenitic steels like AL-6XN.

Nickel-based superalloys are different. Iron accounts for only about 5% of their weight whereas nickel represents around half, depending on the formula.

As a result, nickel-based alloys like C22 or 625 boast excellent toughness and resistance to stress rupture. They also exhibit superior corrosion resistance because a thick passivating oxide layer forms on the surface of the material at high heat.

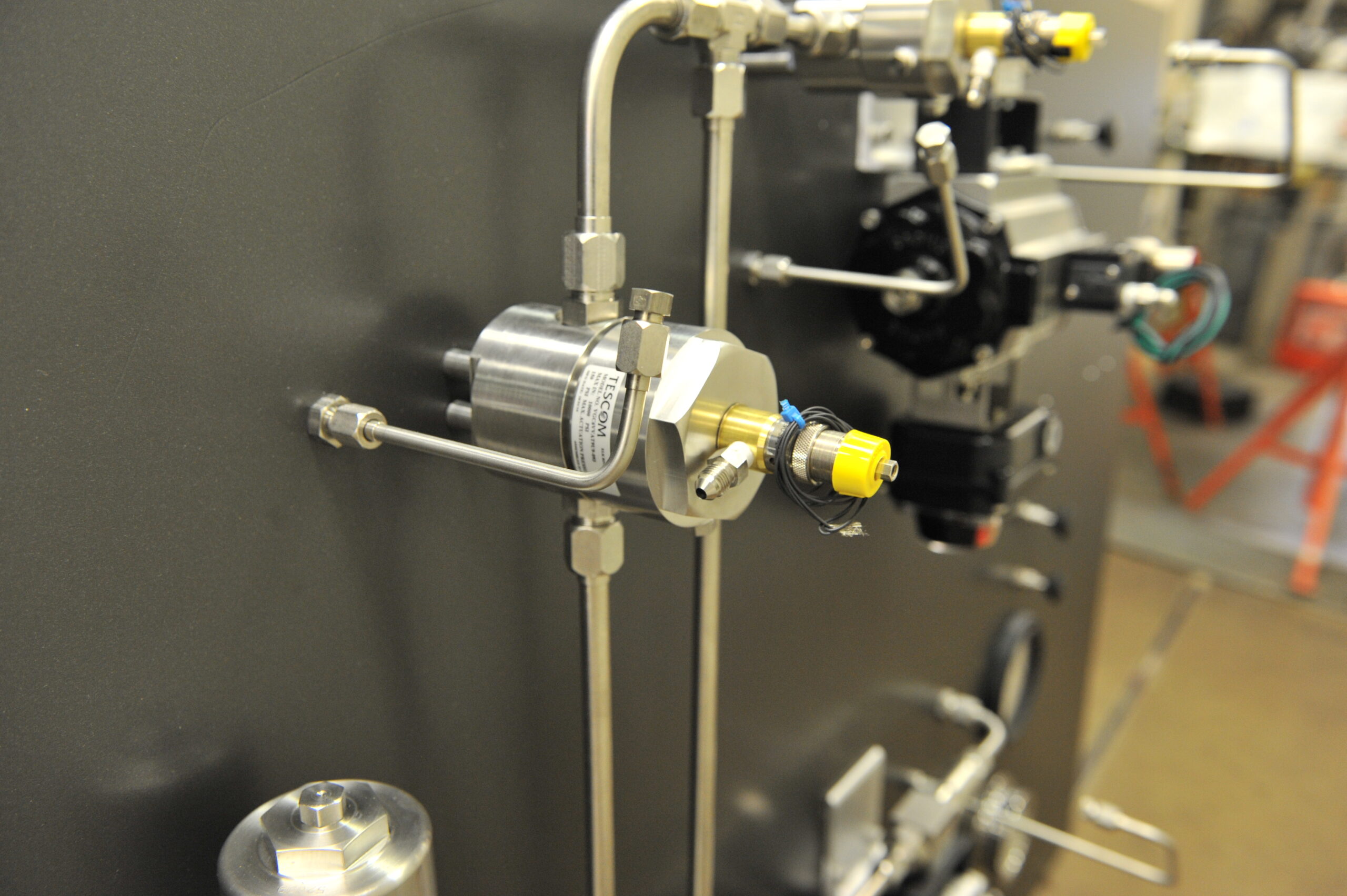

These qualities make nickel-based piping ideal for persistent high-heat, high-stress service in industrial applications such as power generation, oil & gas extraction, pulp & paper where hydrogen lance tips can be in extreme heat environments and manufacturing of chemical or biopharmaceutical products containing chlorides or acids.

Common non-piping applications of nickel-based superalloys include jet engine or power plant turbine blades and rocket booster nozzles.

Don’t trip over trade names

Hastelloy and Inconel are the most common trade names for nickel-based superalloys, but others include Incoloy, Monel and René, to name a few. If you’ve researched nickel-based superalloys for a process piping application, you’ve probably seen these trade names and may have become a little confused.

From the perspective of choosing the best formula for a piping system, trade names are not important.

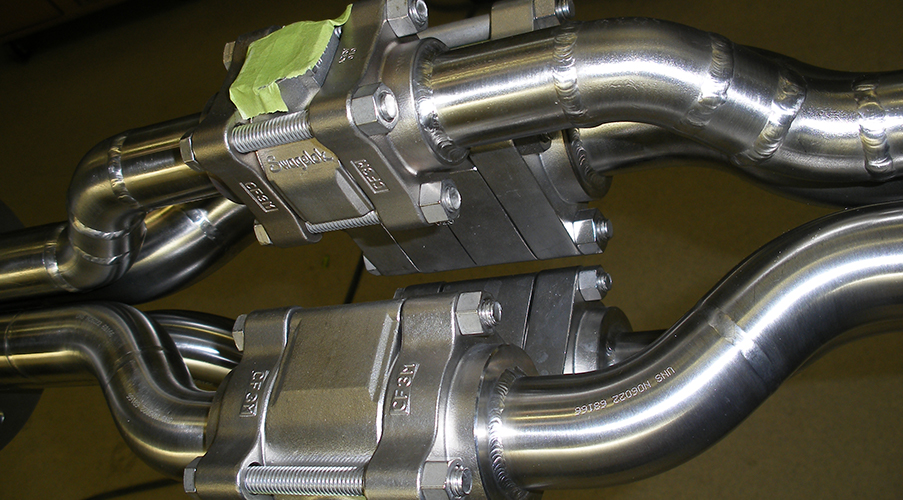

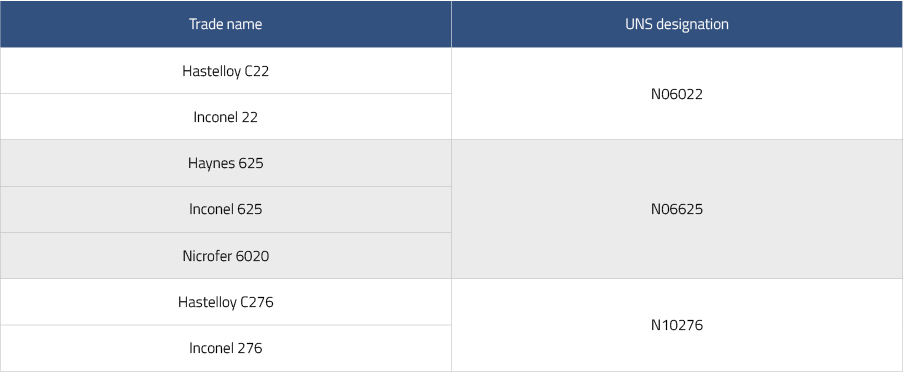

For instance, Hastelloy C22 is a popular nickel-based formula owned by Haynes International. It’s popular enough that users refer to its generic equivalents by that same name—C22. The trade name is irrelevant. The same goes for Inconel 625. Inconel is a trade name owned by Special Metals Corporation; the 625 formula is manufactured by many firms but is colloquially referred to as Inconel even in cases when it’s technically not.

Referring to formulas by their Unified Numbering System (UNS) designations instead of by popular trade names can add clarity. In the chart below, trade names for common nickel-based superalloys are shown along with their UNS designations.

In some cases, engineers specify certain trade names and there’s no flexibility to choose viable alternatives. Other times, specifications are written broadly enough to include alternatives. At High Purity Systems, we can adapt to any customer specification. We’ll get the material and fabricate the system. But we excel when we can provide material selection assistance and constructability and/or design-assist reviews that can reduce project costs and timelines.

Sanitary pipe and tube material selection guide

See how matching materials to processes boosts performance and increases safety in your operations.

Welding Hastelloy, Inconel and other nickel-based superalloys

Among questions we’re most frequently asked is whether we can weld Hastelloy pipe, can we weld Inconel pipe and can we weld Hastelloy pipe to Inconel pipe.

The answer is yes, we weld most nickel-based superalloy formulas. If they can be welded together, our welders can do it.

However, the chemistry of these formulas sometimes dictates whether autogenous welding is possible or if filler metals are required. Also, the welding method used depends on the application in which the material will serve and in accordance with any unique project requirements.

Our expert welders, all of whom are certified to Section IX of the ASME Boiler & Pressure Vessel Code, deal with these scenarios on a case-by-case basis. To keep projects streamlined, we typically recommend the welding method which is easiest to execute while still meeting project requirements.

Expertise in process piping fabrication

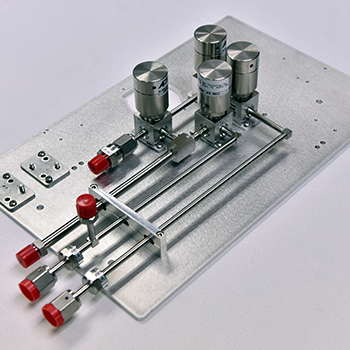

Searching for the process piping fabricator who can build critical systems that stand up to abusive service environments can be difficult. The experts at High Purity Systems combine process and material knowledge with fabrication skill to deliver custom fabricated systems suited for even the most severe service environments.

Our priorities are the same on every job: Meet the customer’s design criteria and find ways to save time and money. Is a process piping project in your near future? What guidance can we offer? Let’s talk.

If you want to continue your research, read about how material selection impacts sanitary process piping applications in our sanitary pipe and tube material selection guide.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.