The heart of efficient operations

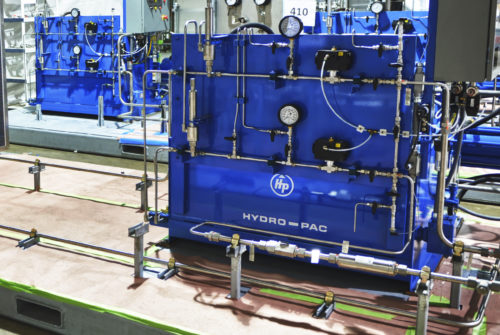

Process piping skids are self-contained environments that include the piping, valves, gauges, pressure regulators, flanges and other necessary components and equipment required to execute manufacturing processes. Process piping systems encompass skidded environments and the piping that moves fluids and gases among them.

This critical infrastructure is at the heart of pharmaceutical, biotechnology, aerospace, food & beverage, brewing, cosmetics and other manufacturing processes. Manufacturers for some of the country’s biggest brands trust the experienced craftsmen at High Purity Systems to build and install custom skids and systems that keep facilities safe, efficient and free of contamination.

Our skid and piping system experience includes:

- Liquid Fueling Facility skids in support of NASA missions to the International Space Station.

- A Reverse Osmosis / Deionized (RODI) water system for a life science lab.

- An upgraded chromatography skid for a pharmaceutical manufacturer.

- Rework of a natural gas supplier’s natural gas piping to improve access for maintenance.

Our welders and fitters follow the strict ASME B31.1 and B31.3 process piping specifications which include ASME Bioprocessing Equipment (BPE) and the SEMI F19 codes. We also provide total transparency by supplying full FDA-compliant documentation of the welds and components that make up your skid or piping system where required.

Advanced design-assist and material expertise

In consumer products manufacturing, profitable operations depend on sanitary systems that run efficiently and are easy to maintain. As costs inflate, margins dwindle and every square inch of the facility becomes more valuable. Facility engineers have increasingly turned to modular systems that boost efficiency and make high-stakes processes easier to monitor and control all within smaller footprints.

We can play a key supporting role during design to ensure the process you envision on paper works in practice. That includes constructability reviews and surveying existing conditions early on to fully understand your need. You know what your process piping skids and systems need to accomplish, and we know how to piece the infrastructure together to do it safely and efficiently while preserving product quality.

Because our team has vast experience working with stainless steel, titanium, Hastelloy, AL6XN and other exotic alloys as well as aluminum and copper, we can recommend cost-saving adjustments in design or material that still guarantee the compliance of your system and the quality of your product.

Early involvement also allows us to order long lead time supplies to stay within your timeline. We cultivate a broad network of suppliers to make sure we have what we need on hand to build your system without delay.

Documentation and field acceptance testing

From beginning to end, the construction and installation of critical process piping systems is strictly regulated by industry standards and some government statutes. It starts the moment raw materials arrive in our facility, where we inspect deliveries to ensure all initial specs are met.

It continues with rigorous documentation. As required per project, the fabrication or assembly of your skid or system is documented and validated by qualified inspectors.

At times, it ends with field acceptance testing, a dry run of a system conducted in our shop to prove it will work as designed before it’s shipped and installed. Depending on the system, an inspector from the customer, the customer’s engineer or a third-party firm will verify the system meets customer specs and is fit for service.

Delivery and installation

After process piping skids or systems are assembled and quality tested, they’re ready for shipment. We take great care to ensure cleanliness during transit. Whether your system is shipped intact or is big enough to require disassembly, everything is properly sealed for transport at our facility.

On arrival, your system is installed—either by our experts or by a third-party installer hired by the customer.

Our priority is keeping our workforce safe during fabrication and installation so that the skid can become an efficient part of operations in your facility. Learn more about how we do it in a wide variety of applications by choosing from the options below. Then, let’s talk. We’re ready to help you build the infrastructure you depend on.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.