Safe, efficient UHP gas distribution

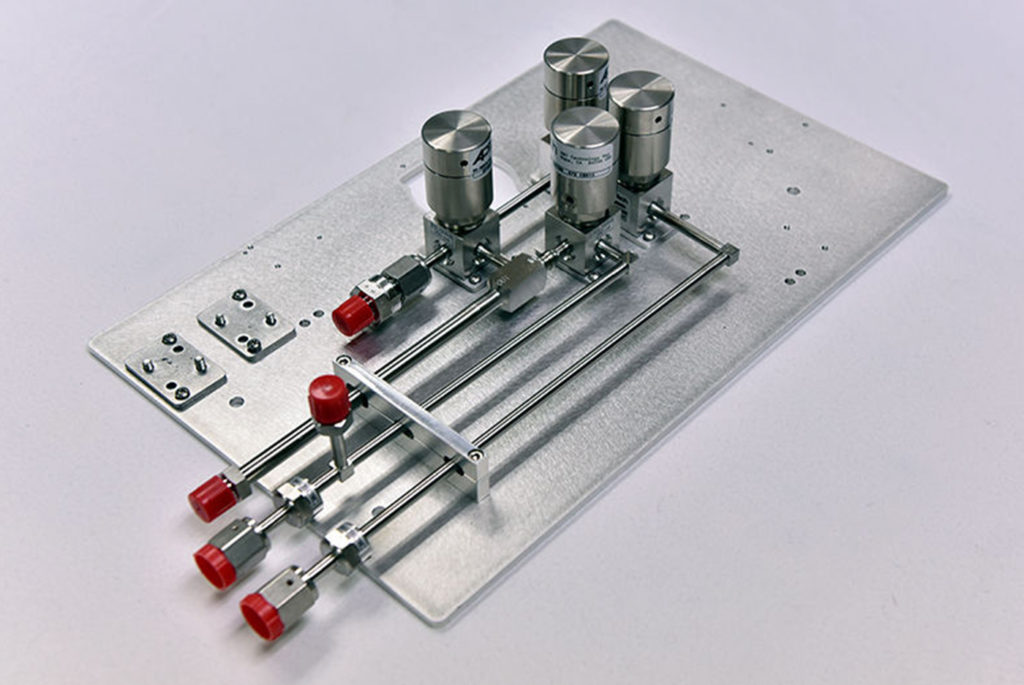

Ultra-high purity (UHP) gas panels provide safe, efficient distribution of process gases when system cleanliness and product purity are critical.

These panels work the same way as valve manifold panels, receiving gas from one or more bulk sources and distributing it among several outlets according to individual downstream processes. However, UHP gas panels are specifically built for microelectronic, semiconductor and photovoltaic component production as well as in some aerospace settings. Those applications require that piping systems and components be built to higher standards to ensure purity of the gasses or fluids being transferred.

UHP gas panels from High Purity Systems assure product purity and system integrity. Sensitive applications require that source gases—and the systems they travel through—stay pure and free of contaminants. Gas type, temperature, pressure, flow rate, corrosion concerns and purity requirements need to be recognized as key design and fabrication variables.

See proof: UHP gas panel fabrication experience

In over three decades in business, High Purity Systems has built UHP systems and components for customers across the country, including these two flagship UHP gas panel projects:

- Fabrication of 19 lightweight purge panels NASA uses for ground support operations.

- Speedy replication of a UHP gas panel following a contamination event in a microelectronics manufacturing facility.

UHP gas panel design

System integrity is the priority of every UHP gas panel project. In some cases, our customers know exactly what they need and simply require a fabricator skilled enough to meet their specs. Other times, we provide design-assist services to help customers identify design and material selection solutions to ensure their systems perform as intended based on the equipment that the gasses or fluids support. We also advise customers in choosing the correct gas regulators, flow meters, high or low pressure valves, manual or automatic valves as well as auto switchover options.

Most specs dictate the use of internal electropolished 316L stainless steel tubing to assemble UHP gas panels. Electropolishing is an electrochemical process that is the reverse of electroplating. It removes material from a metallic surface, resulting in a better roughness average (Ra) of the stainless steel surface. The process significantly reduces the areas available for particulates, bacteria or other contaminants to become trapped. You can relate this to hiking: If you removed the top one-third of all the mountains or hills, it would create a flatter surface that’s easier to travel across.

Smoother surfaces mean there are fewer areas for particulate entrapment and allow gases to flow more freely. The sensitive processes supported by UHP gas panels require very precise delivery of source gas. That precision is at risk if interior surfaces anywhere in the system aren’t within the design specifications.

Cleanroom fabrication

We fabricate UHP gas panels in our in-house cleanroom. Inside this Federal Standard 209e Class 100-certified space, our skilled craftsmen build UHP gas panels using advanced orbital welding techniques and equipment.

Our workmanship is backed by patented, proprietary quality assurance systems including:

- A back purge monitor that regulates the inert gas inside a component so that the most consistent and repeatable welds are achieved for even the smallest part diameters.

- A go/no-go weld profile tool that removes human interpretation (and the risk of human error) from weld quality inspections, providing an objective determination.

After fabrication and inspection, UHP gas panels are double bagged and packaged in the cleanroom so that they stay as clean during shipment and delivery as they were during fabrication.

Trust experience and expertise

For over 30 years, skilled fabricators at High Purity Systems have helped customers guarantee peak performance of new and existing critical systems.

To read more about how we help solve UHP process challenges, browse our aerospace and microelectronics case studies. Are you ready to discuss an upcoming UHP gas panel or other project? Request a quote now.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.