The Challenge

At HPS, we pride ourselves on our diverse fabrication capabilities, which allow us to quickly transition from one job to the next. For instance, one of our recent projects came about when we overheard a client express frustration about an original equipment manufacturer (OEM). The customer, a microelectronics company, was dissatisfied with the OEM’s hefty price tag and long lead time for a valve manifold panel (VMP).

The existing VMP, located in our customer’s gas delivery room, needed to be discarded after one of the gas boxes had become contaminated. Stuck without any replacement panels and scrambling for a solution, the customer could not afford to wait the 12-14 weeks it would take for the OEM’s fabrication to arrive from France. Every hour that our client’s panel was nonoperational was costing them time and money.

The Solution

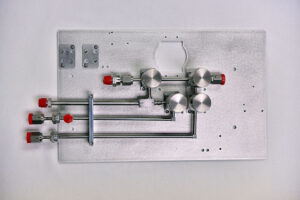

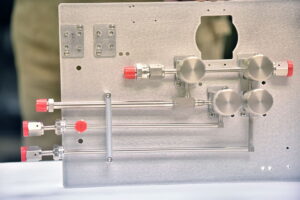

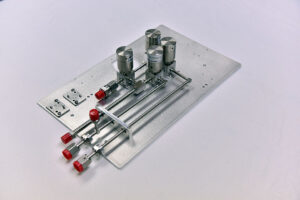

Understanding the urgency of the situation, HPS proposed to fabricate replacements for all of the panels that received gas from the contaminated line. Our team suggested a duplicate panel with the exact same inlet and outlet connections and dimensions as those made by the OEM.

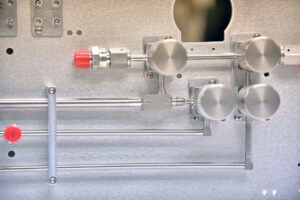

We suggested using alternate valves that offered equal quality and service, despite coming from a different manufacturer. To demonstrate this equivalency, HPS supplied the customer with the cut sheets and specifications for all valves, regulators, venturis, and pressure transducers — all of which they approved.

Obtaining the weld quality you need

Learn about the skills and resources necessary for successful cleanroom welding.

Utilizing an automatic GTAW orbital welding machine, we fabricated a 12 in. x 18 in. stainless steel panel with an electropolished surface finish, complete with the associated components, fittings, and tubing. Our Ultra High Purity (UHP) welds were to semiconductor standards and held tolerances within 0.030 in. of the existing panel dimensions.

The Result

In less than five weeks, HPS was able to duplicate the panel in our Class 100 clean room and provide an OEM replicated solution. The customer was so pleased with the results that they immediately ordered two more panels.

To learn more about HPS’s capabilities or to discuss how we can help you with your next project, contact us today.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.