The Opportunity

Few men and women have given more to our country than the individuals who have returned home disabled after their service. In late 2013, High Purity Systems was honored to be awarded the stainless steel pool and fountain piping for the construction of the American Veterans Disabled for Life Memorial (AVDLM) to recognize these heroic service members.

The memorial stands south of the Botanical Gardens and adjacent to the US Capitol and the House of Representative office building, and interestingly — directly on top of the 395 highway tunnel in the District of Columbia. AVDLM’s design includes etched glass panels, stone walls, bronze statues, and a placid reflecting pool that transitions into a star-shaped pool with an eternally bubbling ceremonial flame.

Many memorials have special water features, such as fountains or pools. These water features require underground specialty stainless steel plumbing that needs to last for many, many years. At AVDLM there is no typical vertical spraying fountain. The star pool is a flowing water pool with a water fall feature over the edges of the star. The other pool has very calm, glass-like water which creates the reflecting pool feature. Below the surface of the calm reflection and the flame, 140 gallons of water per minute are flowing to filter, recirculate, and maintain the proper water levels in each of the two pools. Therefore, all of HPS’ piping is hidden under the pool area and covered with dirt, concrete, granite and etched glass walls.

The Strategy

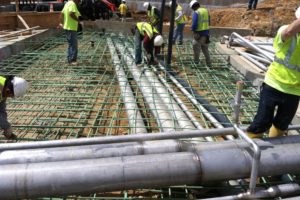

In order for the concrete to be poured on time, allowing the stone masons and landscapers to get to work, our team had to fast-track the piping construction. We detailed the piping in phases and utilized our pipe fabrication shop in Northern Virginia to weld the stainless pipe using the Miller Regulated Metal Deposition (RMD) process. Our off-site fabrication supported our on-site crew of five team members that assembled the fabricated piping spools and completed the final field welds using a TIG process.

The memorial required fill piping, filtration piping, as well as recirculation suction and discharge piping, ranging from 1-1/2” Sch40 to 12” Sch10 stainless steel. These piping systems connected the equipment from inside the pump house to the basin and trough of the star pool and the upper trough, lower trough of the reflecting pool as well as feeding the reflecting pool itself.

Because the job had to be completed in phases (or multiple layers in this case), HPS would alternate installing a layer of pipe and then switch places with another trade to pack dirt or run electrical services. HPS would then return to the site to repeat the process. Being a reflecting pool with thousands of square feet of surface area, fractions of an inch in elevation were critical to the stone work that would cover our piping feeding the pool. Once the underground piping was complete, we focused our efforts on the pump house, where we installed all of the main piping and headers, as well as the finish items such as pressure gauges, temperature sensors, and regulators.

Since this fountain is in Washington DC, where winters include frost and freezing temperatures, all piping had to be installed with a slope back to the equipment vault to allow for complete draining and winterization.

When building an underground piping system to service a beautiful memorial such as AVDLM, it is critical to deliver the best product possible. Every HPS weld was made to the highest standards under ASME B31.3 codes with top quality materials purchased under the Buy American Act.

The Result

HPS was involved in the memorial’s construction for approximately six months, fabricating and installing the pipe, performing multiple stages of hydrostatic pressure testing, and delivered proudly on time.

Once the memorial was completed in October 2014, there was a dedication ceremony for Armed Forces Officers, enlisted service members, and political officials. Many of the behind the scenes individuals and disabled veterans — some of whom were memorialized on the etched glass panels — gave heartfelt speeches about their country, the memorial, and the contractors who built it.

High Purity Systems was honored to be part of the team that built the American Veterans Disabled for Life Memorial, which recognizes and honors those who live every day with the disabilities they incurred while serving our country.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.