When manufacturers build or expand process piping systems, they have a universe of material options to choose from.

Stainless steel—and particularly 300-series formulas—are a popular choice for a wide variety of piping applications. The 304, 316 and 316L stainless steel formulas are the most commonly specified. They feature the right mix of strength, weldability, corrosion resistance and economical cost.

But which of these is the right choice for your application? As we describe below, piping systems perform best when the materials they’re made of match the processes they support.

304 vs. 316 vs. 316L stainless steel properties

304, 316 and 316L stainless steel formulas are austenitic, a term classifying the steel’s crystalline structure. This structure is achieved via heat treatment at very high temperatures followed by quenching—a rapid cooling process locking the structural characteristics in place. Austenitic formulas are stronger than martensitic or ferritic steels. Ferritic steels are magnetic, have a low carbon content and are less corrosion-resistant.

304 stainless steel is the most common stainless formula across industrial and consumer applications. With chromium and nickel alloys, 304 is resistant to many corrosion attacks. It’s also popular in a wide range of applications because no post-weld anneal (a reheating and slow cooling process that relieves stress in metals after exposure to high heat) is required.

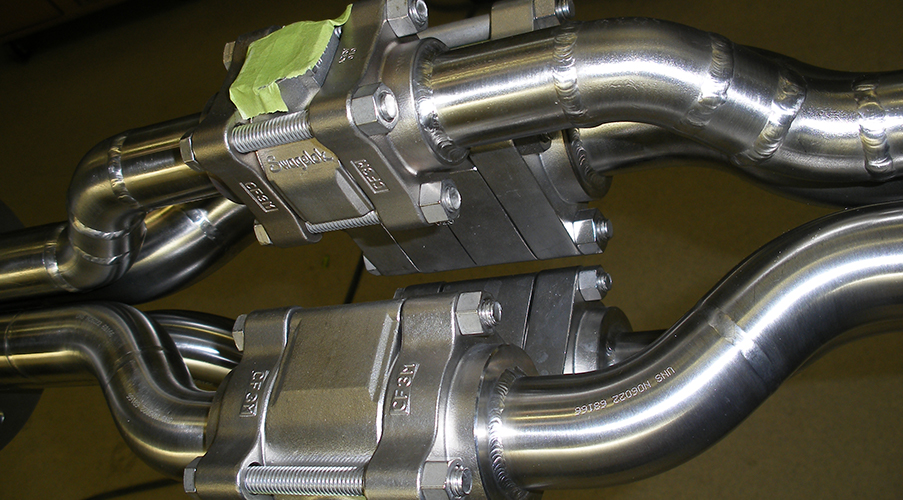

316 stainless steel is similar in chemistry to 304 but also includes molybdenum. That addition makes it much more corrosion resistant. Like 304, the 316 formula does not require post-weld annealing.

316L stainless steel is almost identical to 316. The only difference is the carbon content. 316L’s lower carbon content imparts even better corrosion resistance than 316. 316L does not require post-weld annealing.

Sanitary pipe and tube material selection guide

See how matching materials to processes boosts performance and increases safety in your operations.

300-series stainless steel selection in process piping

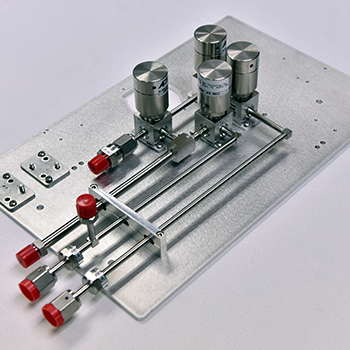

Some manufacturing processes feature strict cleanliness and purity requirements that dictate the kind of piping that can be used.

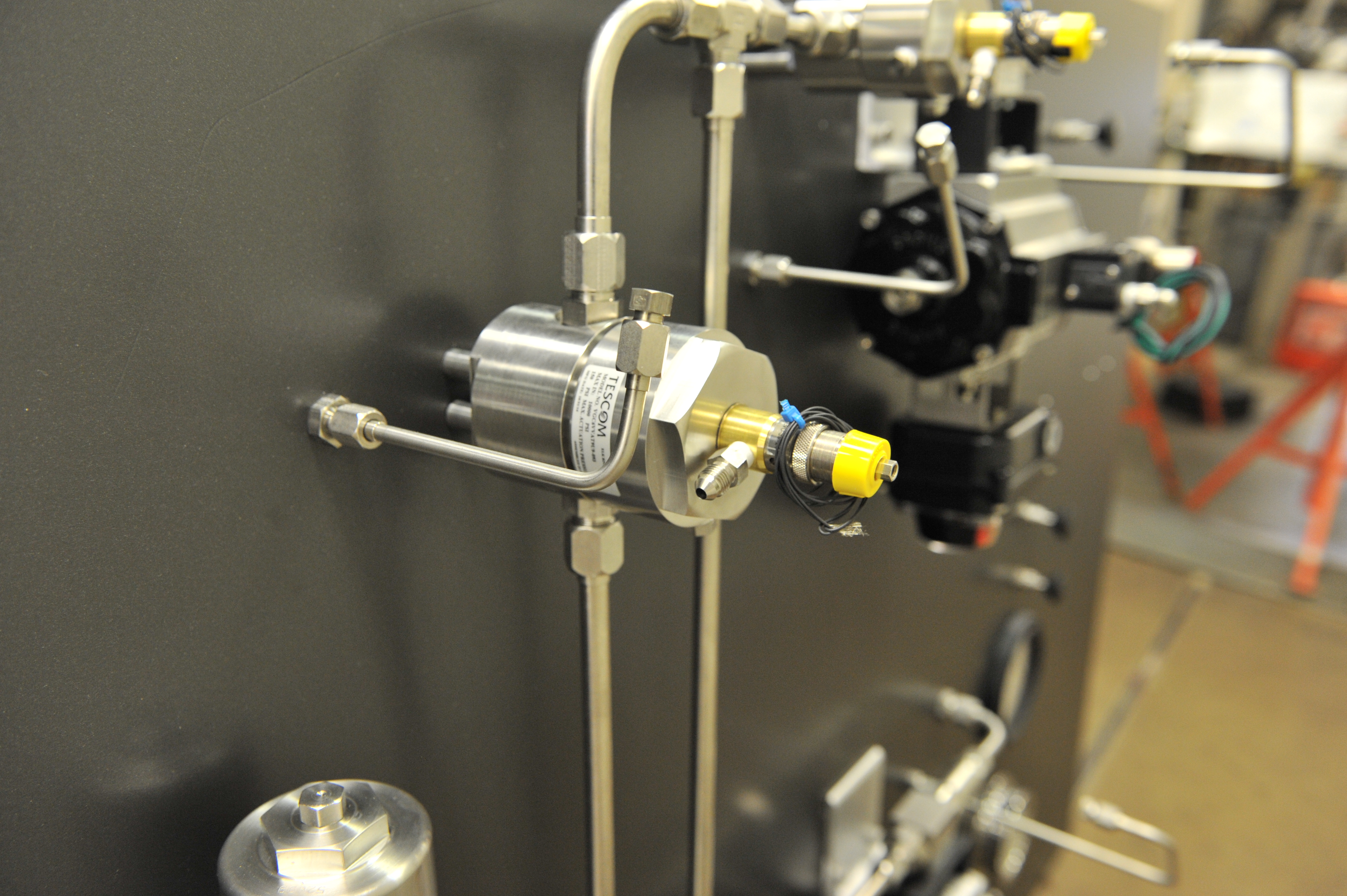

Such is the case in sanitary high-purity pharmaceutical processes or semiconductor manufacturing. In pharmaceutical settings, process piping must be thoroughly cleaned after each batch is made. Electropolished 316L stainless steel is preferred in this setting. Electropolishing produces a much smoother surface with reduced risk of trapping remnant materials from prior batches during cleaning.

Electropolished 316L is also preferred in semiconductor manufacturing, but for a different reason. Semiconductor piping is not cleaned. Rather, these systems remain closed for extended periods of time to protect the purity of the production process. The smooth, corrosion-resistant 316L stainless steel piping ensures the purity of the gas traveling through it is maintained while eliminating entrapment areas for particulates to collect.

304 and 316 steels are specified in applications where corrosion resistance and product purity are still important but which lack the stringent requirements found in pharmaceutical, semiconductor or aerospace manufacturing. Cosmetics and food and beverage processing are examples.

While 300-series stainless steels are very popular, they aren’t universally appropriate for all process piping applications. For instance, even though they’re corrosion-resistant, 300-series formulas do not perform well in the presence of chlorides. Steels with much higher concentrations of alloys like molybdenum, chromium and nickel are preferred in those scenarios.

How High Purity Systems can help

If you’re considering a process piping project, you know that material selection is a key part of getting it off to the right start.

Our team understands the intersection of processes and materials and we’re dedicated to delivering work that makes your processes and systems more efficient. That dedication has kept us on the leading edge of the process piping industry, and is responsible for our successful track record serving some of the biggest brands in the country.

Have more questions about process piping systems or stainless steel formulas? Contact us now. For a broader discussion on how material selection impacts sanitary process piping applications, read our sanitary pipe and tube material selection guide.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.