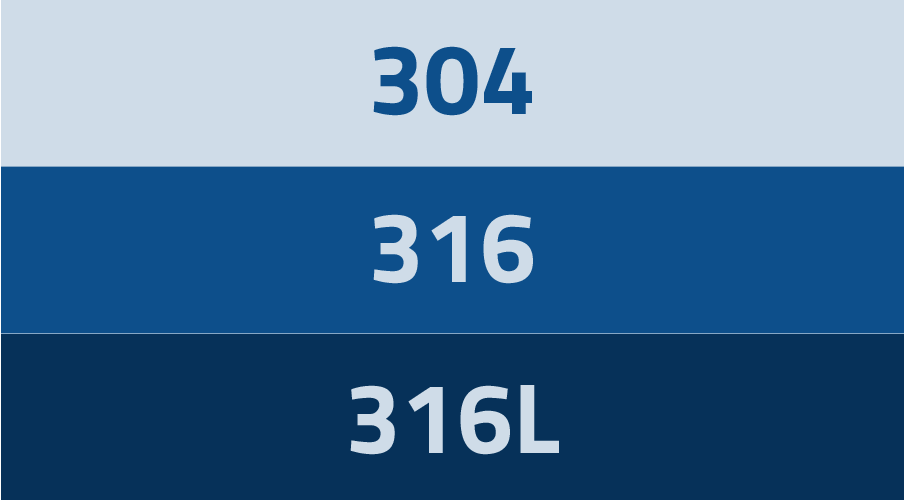

Stainless steel formulas—especially those in the 300-series—are widely regarded as the standard for hygienic and high-purity process piping in a wide variety of applications. They’re the most popular formulas in the industry, but they’re not perfect.

For more severe applications requiring better corrosion resistance and performance at higher temperatures, specialty steel formulas are required.

AL-6XN is one such formula. With much higher concentrations of chromium, nickel and molybdenum, the formula is preferred for the transmission of fluids corrosive enough to eat through traditional stainless steel. As you’ll see, selecting AL-6XN for your process piping application comes with some extra considerations.

AL-6XN properties and applications

AL-6XN was developed for performance in severe environments, including high heat and low-pH processes in a wide variety of industries such as pharmaceutical, medical (sterilization), chemical processing, oil & gas and power generation.

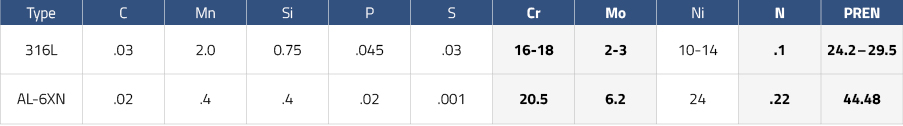

With 2-4% more chromium and around twice the nickel content compared to 316L stainless steel, AL-6XN boasts good stress cracking resistance in the presence of chlorides. The higher molybdenum content imparts better resistance to chloride pitting; slightly more nitrogen provides better strength.

To better visualize how corrosion-resistant AL-6XN is, consider its pitting resistance equivalent number (PREN). Using the PREN formula that accounts for the alloying elements chromium, molybdenum and nitrogen, AL-6XN registers at 44.48. For comparison, the PRENs for 316L and 304 stainless steels are 29.5 and 21.6, respectively.

Sanitary pipe and tube material selection guide

See how matching materials to processes boosts performance and increases safety in your operations.

AL-6XN is a super-austenitic formula. That means its austenite structure as heat treated is stronger and more corrosion-resistant than traditional austenitic stainless steels, such as those in the 300-series. The formula is ideal for low-pH, high-chloride and high-heat applications such as:

- Production of various biopharmaceutical products.

- Municipal and industrial water treatment piping systems.

- Desalination and other processes in marine environments.

- Food & beverage processing featuring high concentrations of salt or vinegar.

- Removal of sulfur dioxide (SO2) from oil & gas plants and trash incinerators.

Alternatives to AL-6XN

Raw material availability plays an important part in designing and building process piping systems. It’s important to be aware of possible alternatives to AL-6XN that will perform just as well but may come with shorter lead times. For example, in higher-heat service, possible alternatives include Hastelloy or Inconel formulas.

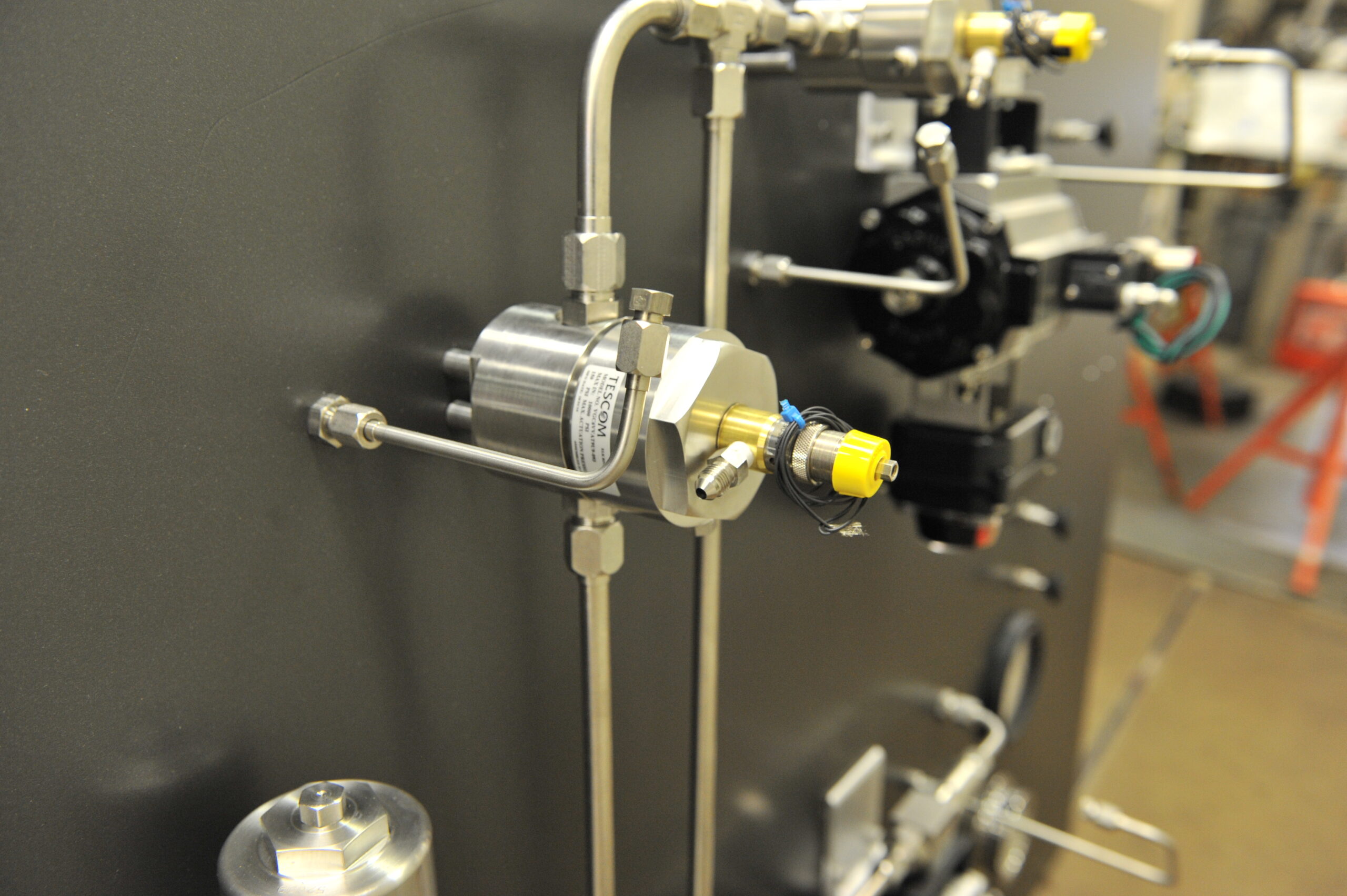

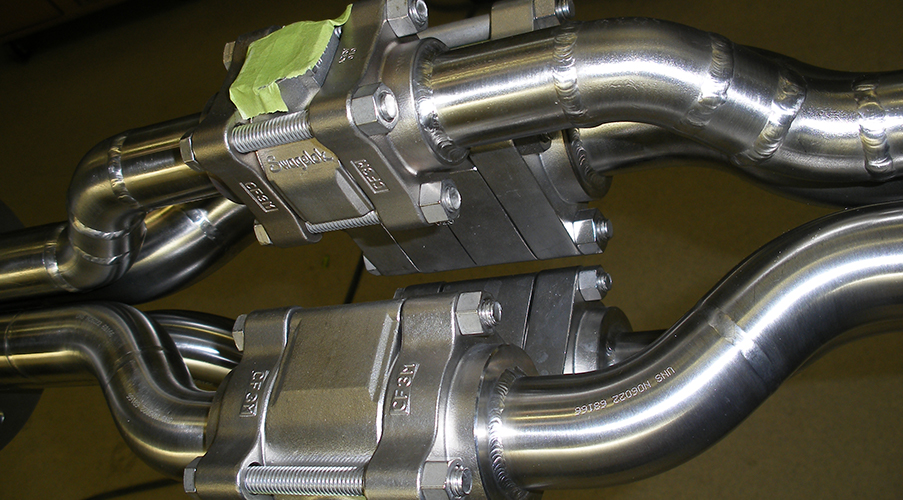

Cutting and welding AL-6XN

Operators must be aware that AL-6XN and other super-austenitic steels behave differently when they’re cut or welded. The higher concentration of alloying elements coupled with the structure of the steel as heat treated means that it must be cut and welded more slowly.

When AL-6XN is cut or welded too quickly, more heat is generated compared to other steel types. It will harden under very high heat, which will negatively impact the quality of the weld as well as its performance in the field. In addition, the structure of AL-6XN wears down saw blades comparatively faster.

Welding outcomes are improved when AL-6XN’s outer surface is cleaned with alcohol or acetone to remove impurities that can affect weld quality. High Purity Systems employs the industry’s most experienced welders, all of whom are ASME Boiler & Pressure Vessel Code Section IX-certified. Learn more about our welding capabilities here.

Get process piping guidance from High Purity Systems

High Purity Systems has built a reputation grounded on understanding customers’ facilities and building process piping systems customized to meet their goals. Understanding how raw materials impact projects is a critical part of that understanding. Read our sanitary pipe and tube material selection guide for a broader discussion on the topic.

Are you considering adding or expanding a process piping system in your facility? Need some guidance on which steel piping formulas will get the job done? Get the conversation started by contacting us now.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.