News

Teamwork, trust & guts: HPS celebrates 35… wait, 36 years in business

At the tail end of 2019 you’d have been hard-pressed to find anyone more excited about 2020 than High Purity Systems. Demand across the industries we serve had been surging....

Fabrication

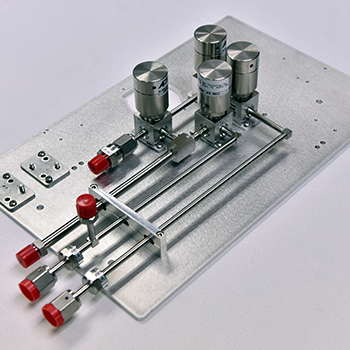

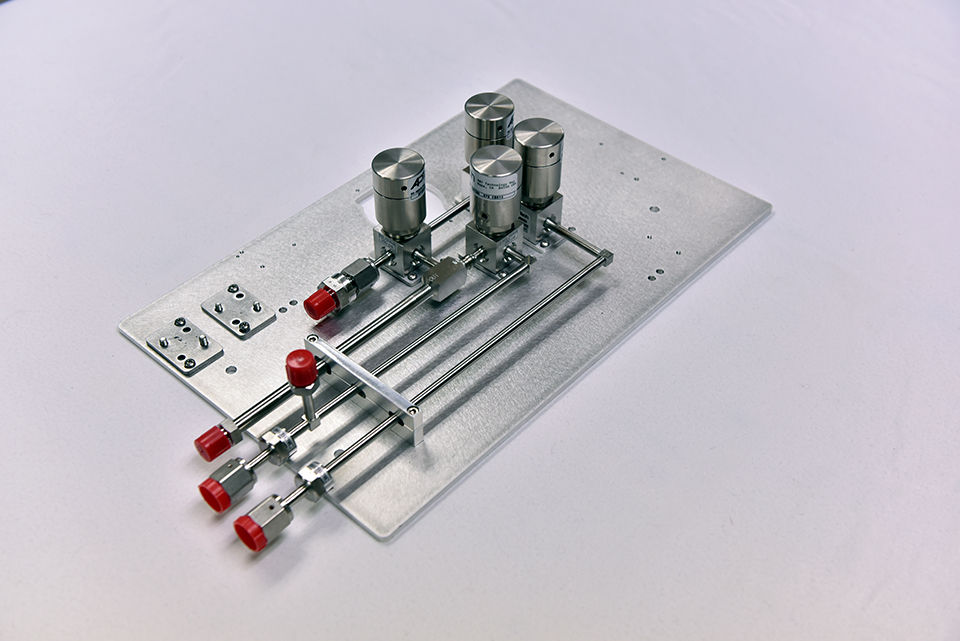

Case study: fabricating 4 launch site ground support control panels

You’d probably be annoyed if your boss dropped another month of work on your desk just as you wrapped up a huge project. It’s a lot different when you’re a...

Fabrication

Understanding stainless steel pipe contamination and managing the risks

Myth: Stainless steel doesn’t corrode. That’s why they call it “stainless.” Fact: It can corrode if it’s not handled properly. Engineers in aerospace, semiconductor, biopharmaceutical and sanitary applications know the...

Fabrication

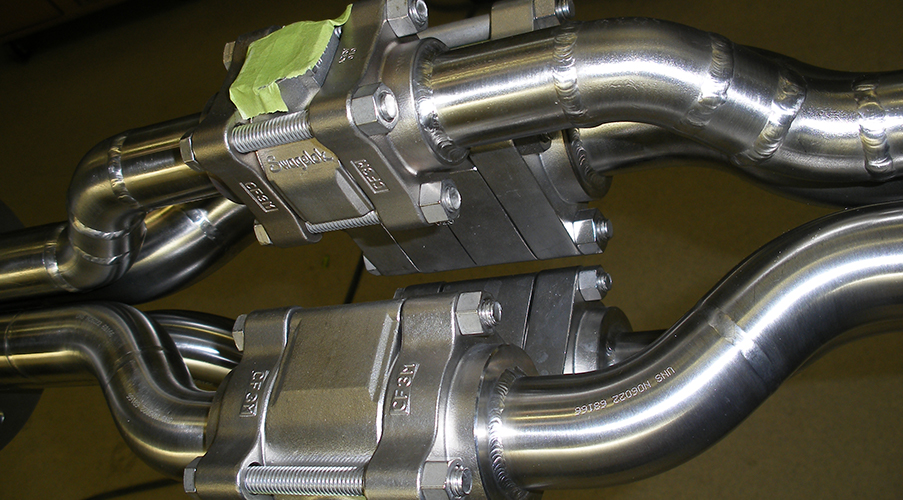

Case study: fabricating 14 launch site liquid fuel skids for NASA missions

We’re in a new space age. Advances in technology and a pioneer’s mindset together drive breathtaking space missions that will park rovers on asteroids and land humans on Mars. None...

News

Virginia Governor praises High Purity Systems expansion

Virginia Gov. Ralph Northam hailed High Purity Systems for its commitment to growing its business and strengthening the regional economy. The praise comes as we move to a larger, 30,000-square-foot...

Cleanroom

Inside our Class 100 / Class 1000 cleanroom

The need for purity within microelectronics and aerospace piping systems is a common topic in our industry. Cleanliness must be guaranteed. Cleanrooms and the welders and fabricators who work in them...

Fabrication

Hastelloy and Inconel pipe for harsh industrial applications

The ways industrial piping systems and components are manufactured have evolved to meet the challenges posed by severe service environments in many industries. In some cases, the transmission and conversion...

Welding

Profiling AL-6XN for severe service industrial piping

Stainless steel formulas—especially those in the 300-series—are widely regarded as the standard for hygienic and high-purity process piping in a wide variety of applications. They’re the most popular formulas in...

Fabrication

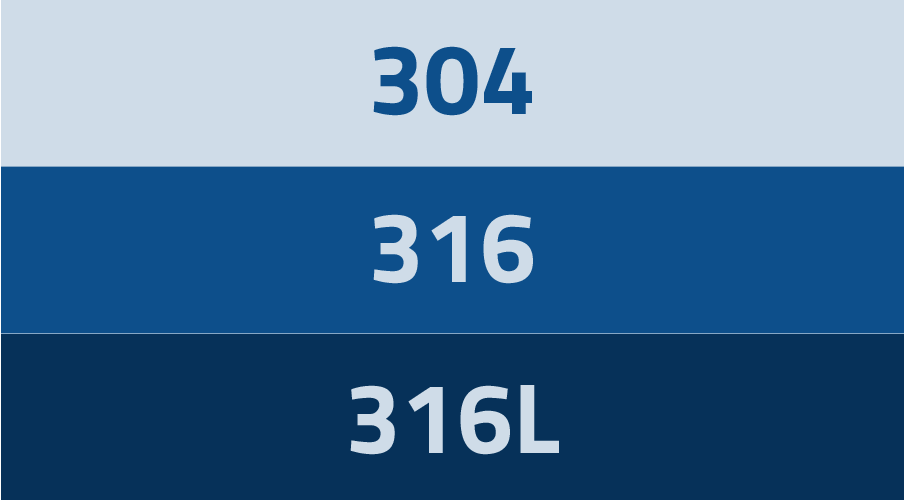

Stainless steel 300-series: Comparing 304, 316 and 316L

When manufacturers build or expand process piping systems, they have a universe of material options to choose from. Stainless steel—and particularly 300-series formulas—are a popular choice for a wide variety...

Fabrication

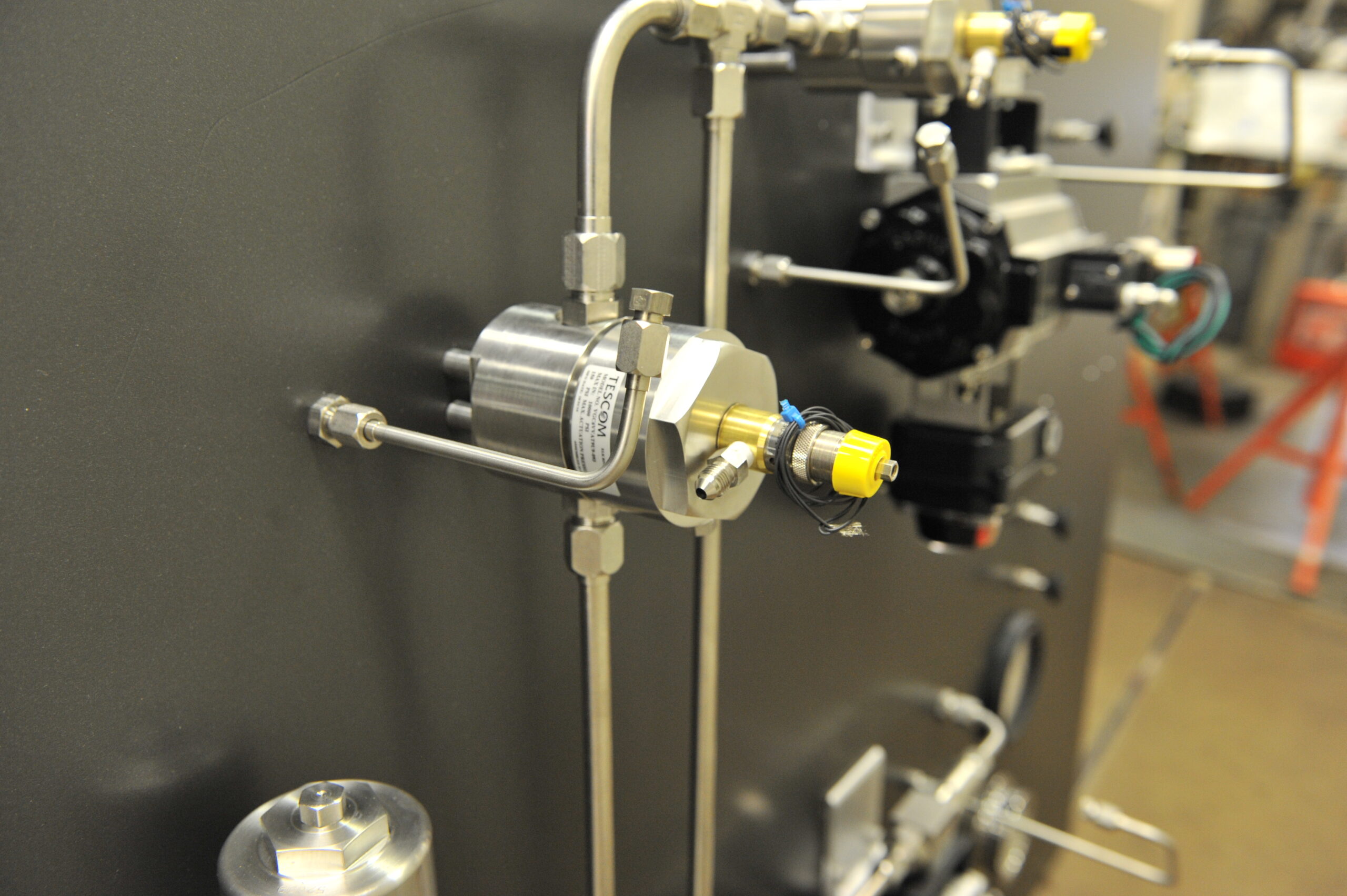

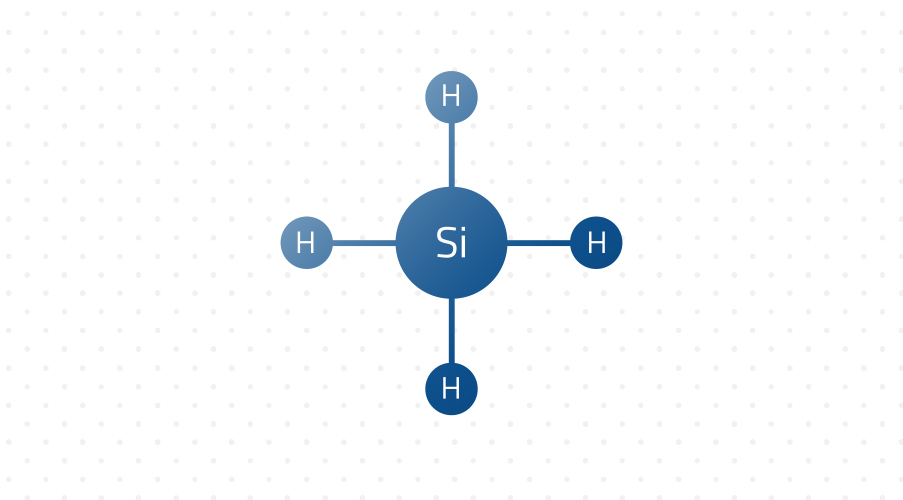

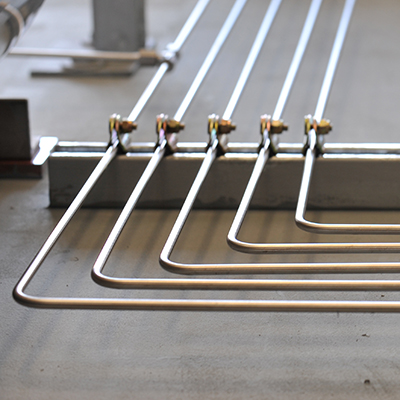

Maintaining quality in silane gas delivery systems

The electronics we rely on, from smart phones to microwaves to thermostats to computer systems in newer cars, wouldn’t exist if not for the silicon-based semiconductor components that make them...

Fabrication

Why would a mechanical contractor consider outsourcing piping fabrication?

Using off-site fabrication for piping spools — prefabricating products in a dedicated facility before having them delivered and installed on a job site — drastically reduces the schedule, cost and...

Fabrication

4 Time and Cost Saving Advantages of Prefabrication

Prefabricating industrial piping in a dedicated facility offers several advantages over the on-site alternative, especially during testing and finishing processes. When performed directly on the job site, these secondary services...

Welding

Does HPS Provide Dissimilar Metal Welding Services?

To ensure successful welding of dissimilar metals, it’s important to partner with only highly experienced, expert welding fabricators. Typically, when customers venture outside the realm of standard materials, costs increase...

Welding

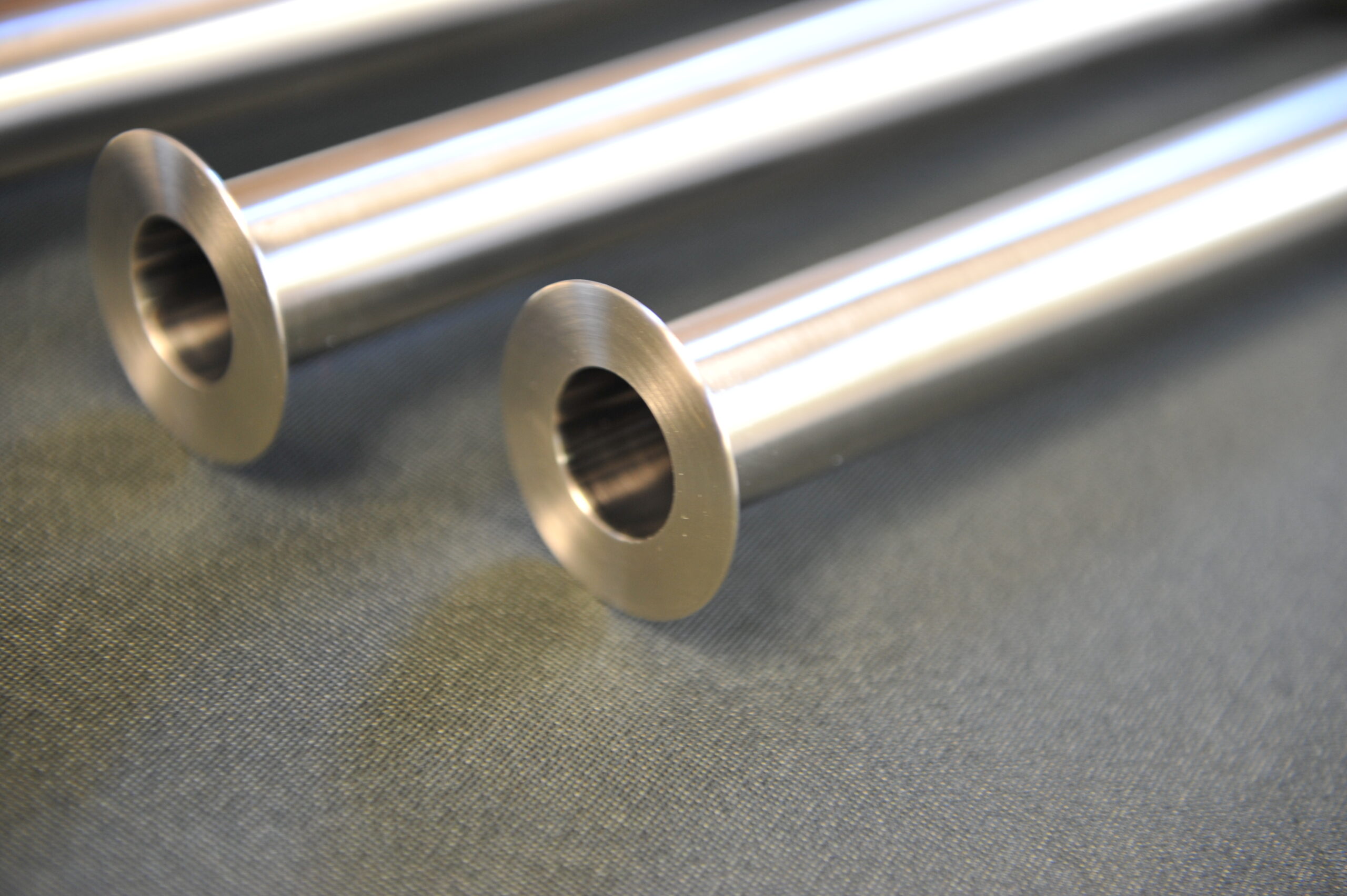

Can HPS Provide Tank Components Like Dip Tubes?

The short answer is “Yes!” but we’ll give you the long one anyway. For years, customers have relied on HPS to fabricate a wide variety of standard and custom tank...

Cleanroom

Replicating High-Purity Components to Match OEM Specifications

We often hear from our customers that they feel at the mercy of original equipment manufacturers (OEMs) when procuring system replacement parts. Since OEMs rarely build their own parts, they...