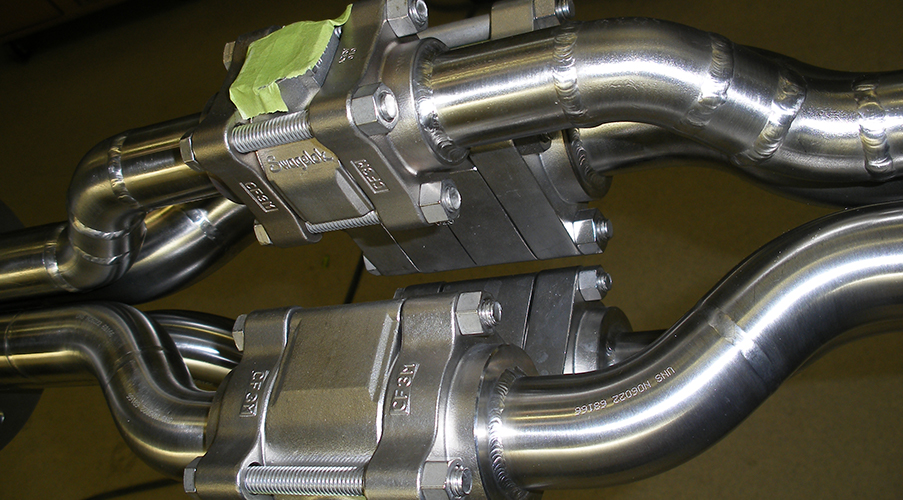

Using off-site fabrication for piping spools — prefabricating products in a dedicated facility before having them delivered and installed on a job site — drastically reduces the schedule, cost and inefficiencies that are encountered during onsite fab. While some mechanical contractors are quick to opt for onsite fabrication, the most successful and forward-thinking contractors are choosing outsourced fabrication as part of their overall business strategy.

The Decision Making Process

The success of off-site fab — and the project as a whole — depends on the early decision-making process. When contractors choose off-site third-party fabrication, they are making a carefully considered office-level decision; however, many contractors instead make field-level decisions, committing to onsite fab because “that’s the way they’ve always done it”.

The success of off-site fab — and the project as a whole — depends on the early decision-making process. When contractors choose off-site third-party fabrication, they are making a carefully considered office-level decision; however, many contractors instead make field-level decisions, committing to onsite fab because “that’s the way they’ve always done it”.

For example, a field foreman, though highly skilled at his craft, is often not responsible for the bottom line profitability of the project. Yet, the field foreman often makes decisions that directly impact project profitability, including fabbing onsite.

Strategic Off-Site Fabrication

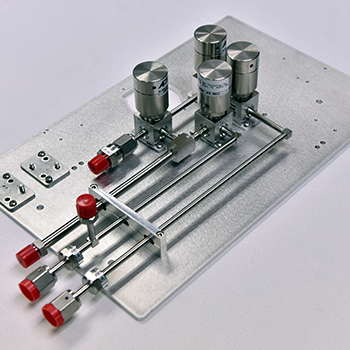

A strategy-focused contractor will instead view off-site fab as part of their successful business model. Outsourced off-site piping fabrication allows the onsite mechanical contractor to better manage a variety of factors, including labor costs, quality, rework, safety and schedule. Outsourcing fabricating also allows the mechanical contractor to take on larger projects without having to hire skilled labor resources.

Reduce risk, lower cost and guarantee the highest quality work with off-site piping fabrication.

Minimize construction risks with off-site piping fabrication

The Importance of Quality

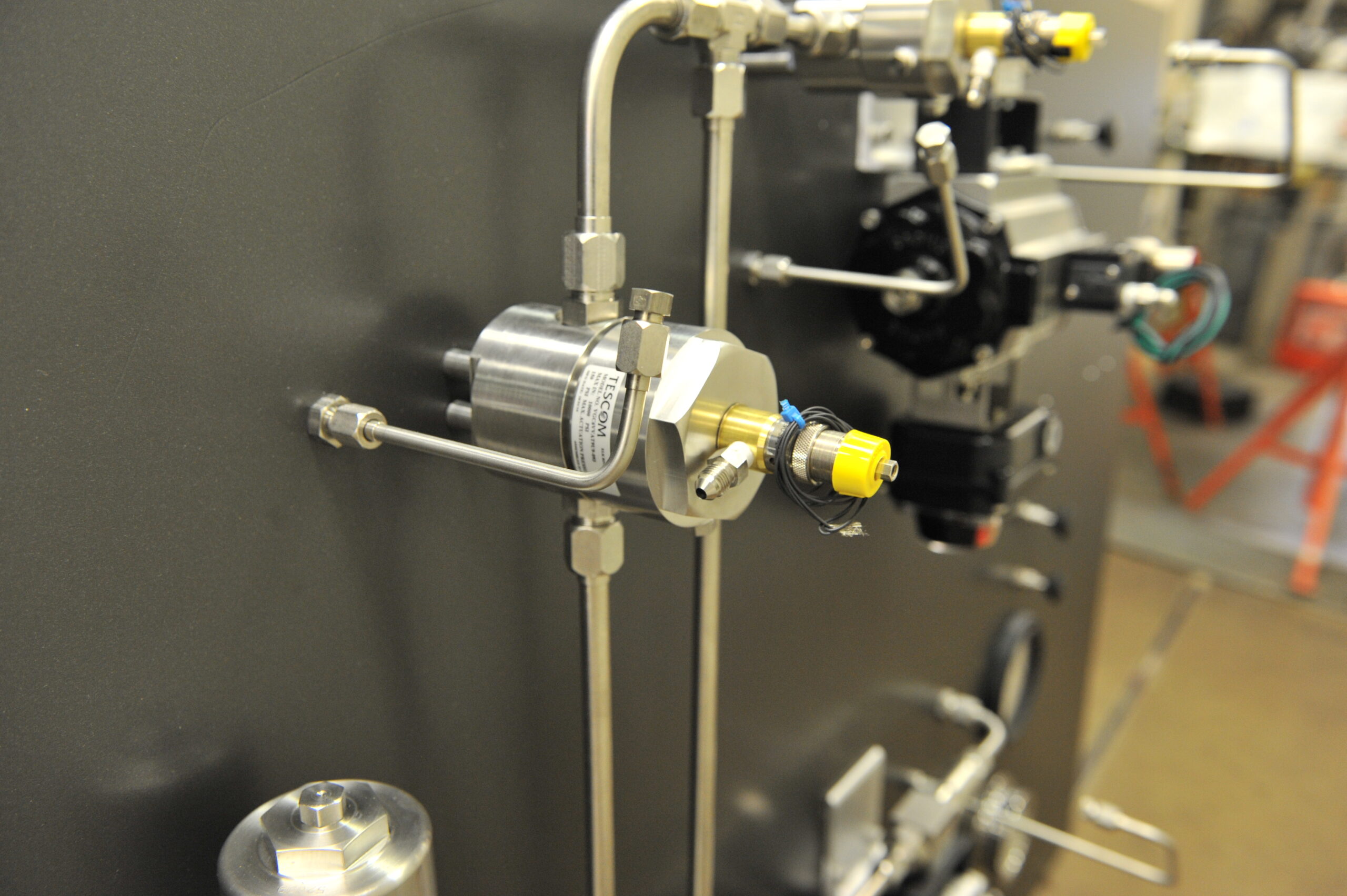

It is easier to attain consistent weld quality in a controlled environment, than on a project site where the conditions are ever-changing. Additionally, an experienced pipe fabrication shop will have long established QA/QC procedures that ensure the work is done right the first time.

An experienced off-site fabricator will help you reduce project impacts while addressing technical details — from CAD drawings and measurements to spooling and job site deliveries.

To learn how pre-fab piping spools from HPS can enhance efficiency and cost savings for your next project, contact the team today.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.