The Challenge

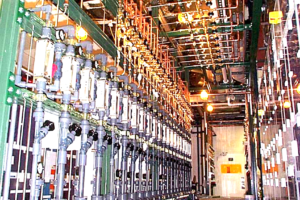

Site managers face a number of challenges when maintenance work is being performed in their manufacturing facility — namely, ensuring that the regular schedule of the plant is not interrupted. A High Purity Systems (HPS) customer recently faced this when preparing to cap and remove the process gas and water services originating from the main supply lines located in the ceiling of their plant.

The customer, a global leader in government and defense contracting, needed a company that could remove the process gas piping competently, as cutting the wrong line or turning off an incorrect valve would have devastating effects on production. That’s why they turned to the HPS team and our three decades of hands-on field experience and industry expertise, and an outstanding safety record for demolishing piping systems.

The Strategy

Instead of simply picking the lowest bidding contractor, the customer selected HPS because of our extensive knowledge of their facility — and in the end, our proposal also turned out to be the most cost-effective solution. Not only did we cap and demo the lines as required, but we finished the project with no disruptions to production as our customer had originally anticipated.

According to the job specifications, the project called for a high purity nitrogen line to be capped using a silver solder brazing method. The HPS team was able to provide an alternate solution involving a copper ProPress tool, a faster and less expensive method than silver solder brazing. This method eliminated the need for hot work permits, soldering, a fire watch, testing and recertification.

The Result

The customer trusted HPS’ judgment and ability to work safely and efficiently while adhering to a time and materials contract. As a result, we were able to provide a superior solution that brought the project in under budget. In fact, they were so impressed with the final product, our 100% accuracy, and our ability to go above and beyond to benefit the project that they have kept our time and materials contract open for future work.

Contact us today to learn more about how High Purity Systems can earn your TRUST and put our 30 years of experience to work improving your projects.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.