Pure execution

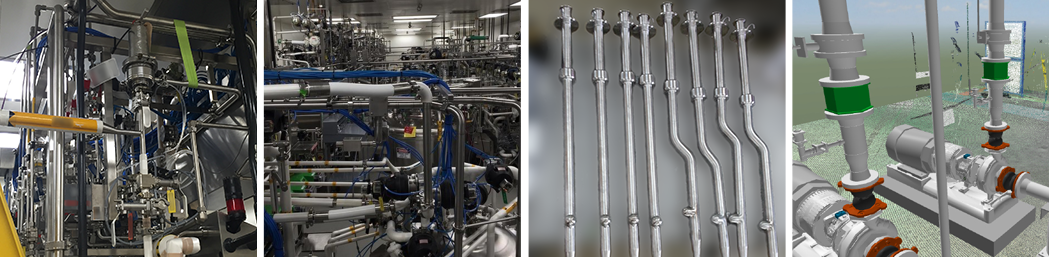

The stainless steel process piping and components in biopharmaceutical manufacturing facilities must be nothing short of flawlessly made and backed by complete turnover documentation.

Since 1985, High Purity Systems has provided process piping fabrication and installation for new construction or system modifications so biopharmaceutical manufacturers can continue their life-saving and life-sustaining work.

Quality craftsmanship

HPS’s craftsmen are among the most highly skilled in the world. These ASME BPE B31.3-certified experts excel in:

Simply put, quality craftsmanship matters above all else in biopharmaceutical manufacturing facilities (cGMP). “Good enough” is not good enough. It must be exactly right the first time.

Chromatography Skid Steam Valve Removal and Modifications

Without a complete Turnover Package, your investment is worthless

An investment in biopharmaceutical process piping infrastructure is no better than a sunken cost if its accompanying documentation is a mess.

If the FDA or other regulators come calling, you need to be confident that what you show them proves your process piping infrastructure meets their standards for producing life-saving or life-sustaining products and can be validated.

That’s why Turnover Packages (TOPs) are always accurate and always complete. If something is missing, we’ll find it and make it right — right away.

Chasing subcontractors down in search of vital information is a costly, time-intensive risk you cannot afford to take. When you work with HPS, you won’t have to.

New Pure Water System Installation

Expanded fabrication show gives us more room to work

Shutting down production to bring specialty piping contractors on-site constitutes a major risk for biopharmaceutical manufacturers. Often, system repairs, modifications or expansions can only occur within one brief window each year.

HPS minimizes risk and makes the most efficient use of shutdowns by taking as much fabrication work off-site and into the shop as is feasible.

Our 30,000-square-foot fabrication shop includes a 5,000-square-foot dedicated stainless steel bay where raw materials and works in progress are stored and staged. Strict enforcement of shop procedures assures the prevention of stainless steel contamination in our facility.

Virginia Governor praises High Purity Systems expansion

Why HPS is different

Biopharmaceutical facility leaders need the best of the best working on their process piping projects. In the end, it’s all about making sure you’ve got the right partner.

HPS fields an exceptionally strong team of project executives, project managers, superintendents, foremen, certified welders, pipefitters and a BIM/VDC staff who’ve spent their careers building knowledge of customer facilities and challenges. They’re led by a nimble, committed executive leadership team that stays involved for the duration of a project.

Put them together and you get why we’re different. And it’s not just what we do — it’s how we promise to do it:

- By being long-term problem-solving partners who bring true production solutions to the table

- By always submitting accurate, comprehensive, transparent bids up front

- By setting a “no punch list” goal on every project

- By genuinely caring for our customers, our community and each other

Learn more about who we are or request a quote for your next biopharmaceutical process piping project now.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.